Towards an off-grid site

Study objectives

This study has for objective to compare different technologies and energy system architectures for the supply of electricity to an off-grid site. The targeted applications are many: telecommunication tower, autonomous meteorological station, industrial site or, like treated in this present study, a tertiary building.

The compared technological solutions in this study are:

- An electricity production and storage system comprising a photovoltaic power plan, a diesel generator and Li-ion batteries (PV-Bat-Genset);

- An electricity production and storage system comprising a photovoltaic power plan and Li-ion batteries (PV-Bat);

- An electricity production and storage system comprising a photovoltaic power and a storage solution hybridizing Li-ion batteries and a complete hydrogen chain including hydrogen production, storage and use to produce electricity (PV-Bat-H2).

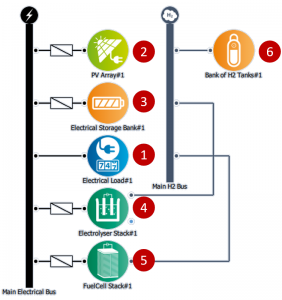

Architecture example – PV-Bat-H2 System

This figure illustrates an example of architecture modeled with the software Odyssey. This solution comprises the following components:

- The electrical load to power

- The photovoltaic power plant

- The Li-ion batteries

- The electrolyzer

- The fuel cell

- The hydrogen tank

The operation principle consists in producing electricity form the photovoltaic power plant to power the electricity needs of the site. When a surplus of electricity is available, it is used to charge the batteries and/or power the electrolyzer to produce hydrogen which will be stored in the tank. Inversely, when the photovoltaic production is insufficient to power the electricity needs of the site, the batteries and/or the fuel cell are used to complete this production.

The trade-off between the use of batteries and the hydrogen chain is driven by the energy management strategy. Thanks to software ODYSSEY, several strategies have been tested and optimized.

Examples of results

Focus on the PV-Bat-H2 solution

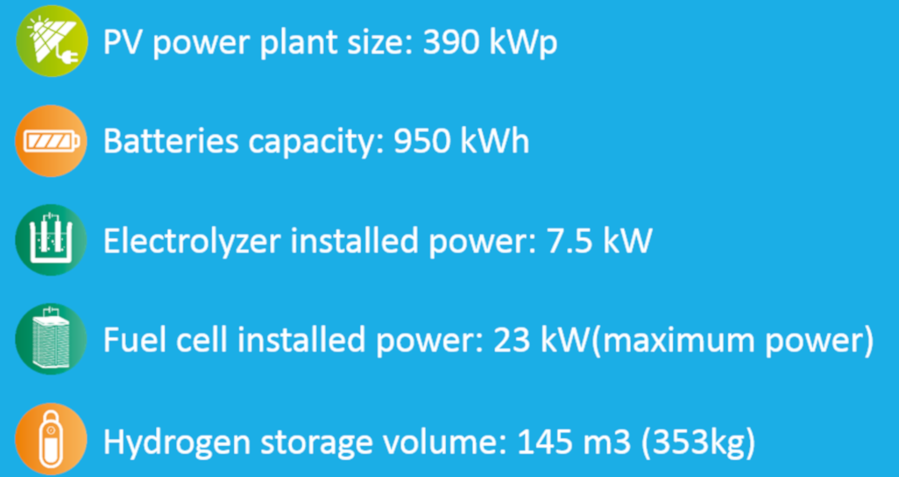

Thanks to Odyssey software, the sizing of the PV-Bat-H2 solution has been optimized with the objective to obtain a fully autonomous site in electricity. The obtained sizing, illustrated on the right, shows that a “small” hydrogen chain is enough to complete the batteries. The hydrogen chain is used here as a way to extend the autonomy of the batteries.

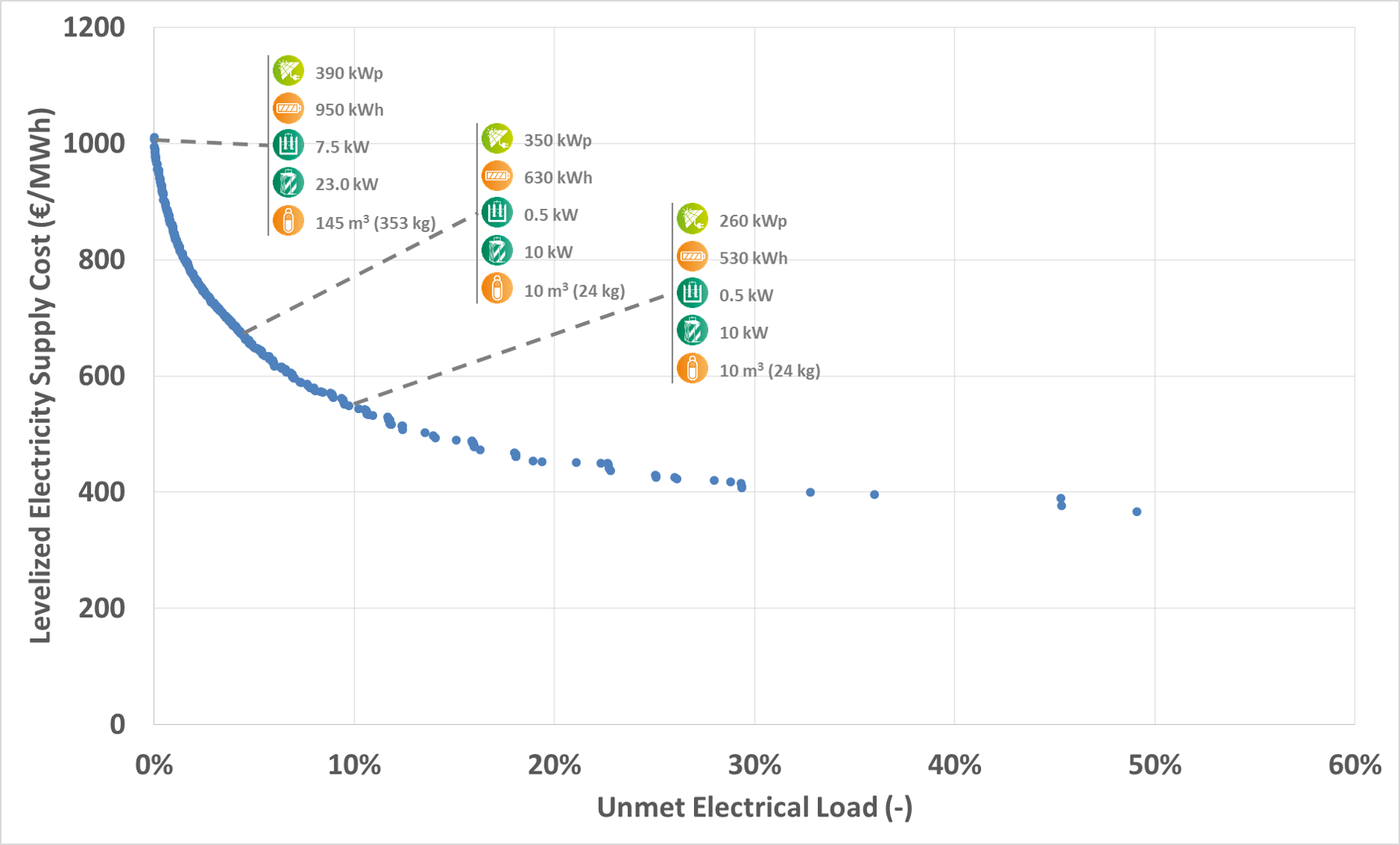

This figure illustrates the energy supply cost (levelized on a 20 years period and expressed in €/MWh) for different supply failure rates (rate of unsatisfied energy needs). Each blue dot corresponds to the optimal sizing of the PV-Bat-H2 solution for a given supply failure rate, in other words, the sizing allowing to minimize the energy supply cost for a given supply failure rate.

We can observe that for a supply failure rate of 10% (a 90% autonomous site), the energy supply cost is reduced by half in comparison to a 100% autonomous site. This highlights that reaching a completely autonomous site can require an important extra cost. We observe also important variations in the optimal sizing of the solution (PV, batteries, electrolyzer, etc.) depending on the acceptable supply failure rate. This highlights the importance of the sizing phase in the conception of an energy system in order to guaranty compliance with specifications. It is indeed required to sufficiently size the different components to maintain the system below the maximum allowed supply failure rate at all time while avoiding over-sizing which will necessarily lead to a more expensive solution.

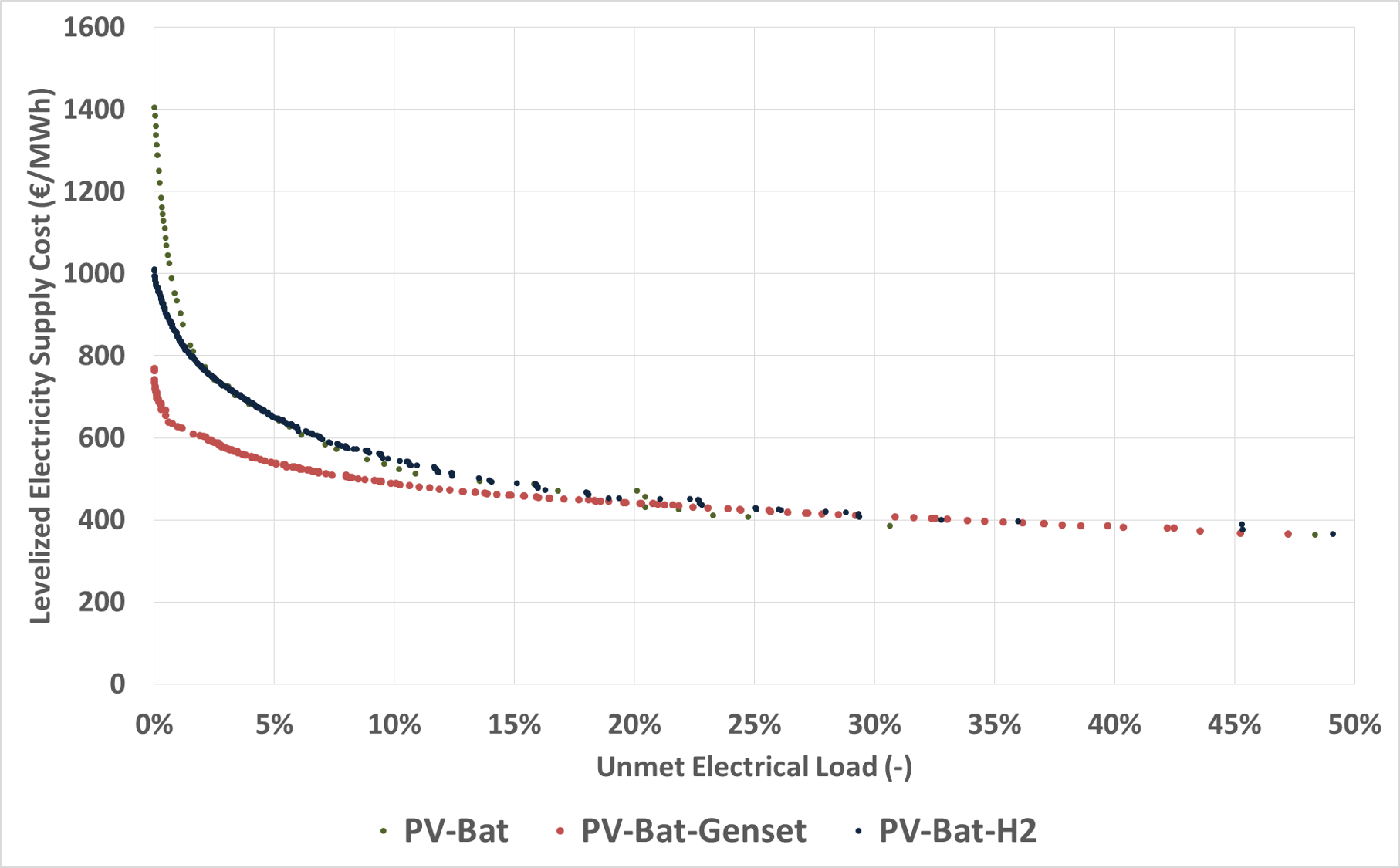

Comparison of the different solutions

This figure compares the three solutions investigated within this study. Similarly to the previous figure, each point corresponds to the optimal sizing of a given solution and leads to a given supply failure rate. We can observe that to maintain a supply failure rate below 20% (site autonomy of 80%), the PV-Bat-Genset solution is the most competitive (for a diesel cost assumed here at 1.0€/l).

We also observe that for a supply failure rate above 3% (site autonomy below 97%), both the PV-Bat and PV-Bat-H2 solutions are equivalent. However, as soon as an autonomy above 97% is desired, the solution PV-Bat-H2 becomes economically more attractive.

Main conclusions

The solution combining a PV power plant, batteries and a diesel generator remains today the most competitive option to guaranty a total autonomy of the site (for a diesel cost at 1.0€/l). However, this evaluation does not take into consideration CO2 emissions or other impacts on the environment due to the use of the diesel generator.

Among the two other 100% renewable energy based solutions, the one integrating a PV power plant, batteries and a hydrogen chain constitute an attractive alternative, in comparison to a solution with batteries only, from an economic point of view. The extra investment in the hydrogen chain allows indeed to considerably reduce the batteries capacity required for an autonomous site resulting in a solution with a lesser complete cost over the 20 years period.